Enos printing corp uses a job order cost system – In the realm of cost accounting, Enos Printing Corp stands as a beacon, showcasing the effectiveness of the job order cost system. This meticulously designed system empowers businesses like Enos Printing Corp to allocate costs accurately, track expenses diligently, and enhance decision-making processes.

The journey of Enos Printing Corp, a prominent player in the printing industry, exemplifies the advantages of employing a job order cost system. By delving into their operations and examining how they leverage this system, we uncover valuable insights into its functionality and benefits.

Job Order Cost System

A job order cost system is a cost accounting system that is used to track the costs of individual jobs or orders. This type of cost system is typically used by businesses that produce unique or custom products or services.

The key features of a job order cost system include:

- Each job is assigned a unique job number.

- All costs incurred for a job are accumulated in a job cost sheet.

- Job cost sheets are used to track the progress of jobs and to determine their profitability.

The benefits of using a job order cost system include:

- Improved job costing accuracy.

- Increased visibility into job profitability.

- Better control over job costs.

Businesses that typically use job order cost systems include:

- Manufacturers of custom products.

- Service providers that offer unique services.

- Construction companies.

Enos Printing Corp

Enos Printing Corp is a commercial printing company that provides a variety of printing services, including offset printing, digital printing, and wide-format printing.

Enos Printing Corp uses a job order cost system to track the costs of its printing jobs. This system allows Enos Printing Corp to accurately track the costs of each job and to determine its profitability.

The specific advantages of using a job order cost system for Enos Printing Corp include:

- Improved job costing accuracy.

- Increased visibility into job profitability.

- Better control over job costs.

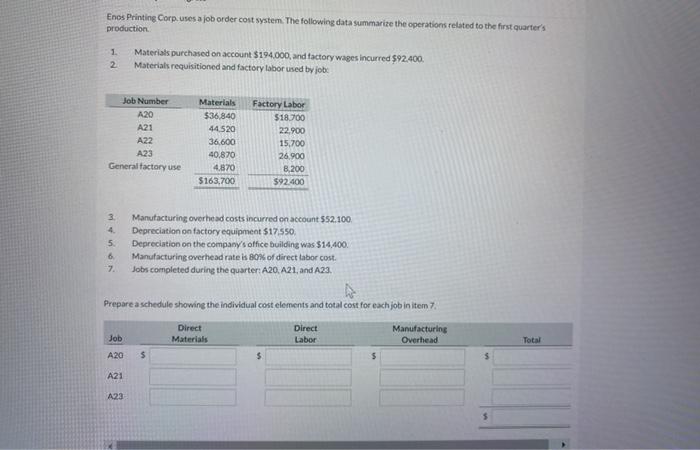

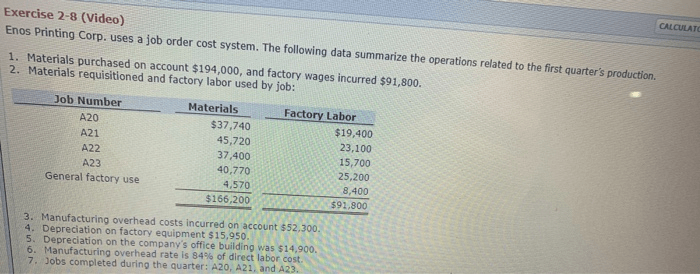

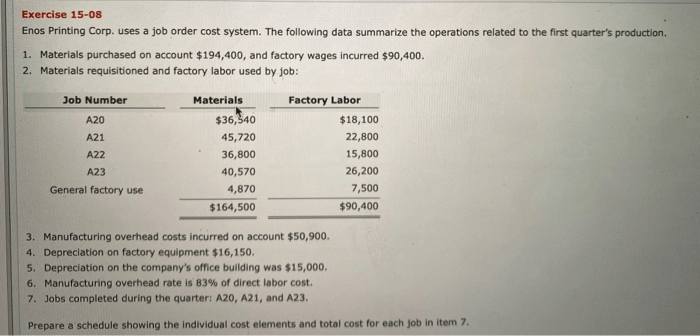

Cost Allocation and Accumulation: Enos Printing Corp Uses A Job Order Cost System

In a job order cost system, costs are allocated and accumulated to jobs using a variety of methods. The most common methods include:

- Direct costs are costs that can be directly traced to a specific job. Examples of direct costs include materials, labor, and shipping.

- Indirect costs are costs that cannot be directly traced to a specific job. Examples of indirect costs include rent, utilities, and depreciation.

Overhead costs are a type of indirect cost that is applied to jobs based on a predetermined rate. The most common methods for allocating overhead costs to jobs include:

- Activity-based costing (ABC) allocates overhead costs to jobs based on the activities that are performed on each job.

- Traditional costing methods allocate overhead costs to jobs based on a predetermined rate, such as a percentage of direct labor costs or machine hours.

Enos Printing Corp uses a traditional costing method to allocate overhead costs to its printing jobs. The company uses a predetermined overhead rate of 150% of direct labor costs.

Job Costing Procedures

The key steps involved in job costing include:

- Identify the costs to be included in the job.

- Allocate the costs to the job.

- Accumulate the costs in a job cost sheet.

- Calculate the total cost of the job.

Job cost sheets are used to track the costs of jobs and to determine their profitability. Job cost sheets typically include the following information:

- Job number.

- Customer name.

- Description of the job.

- Date the job was started.

- Date the job was completed.

- Total cost of the job.

Time tickets and material requisitions are used to collect the costs that are included in job cost sheets. Time tickets are used to track the time that employees spend on each job. Material requisitions are used to track the materials that are used on each job.

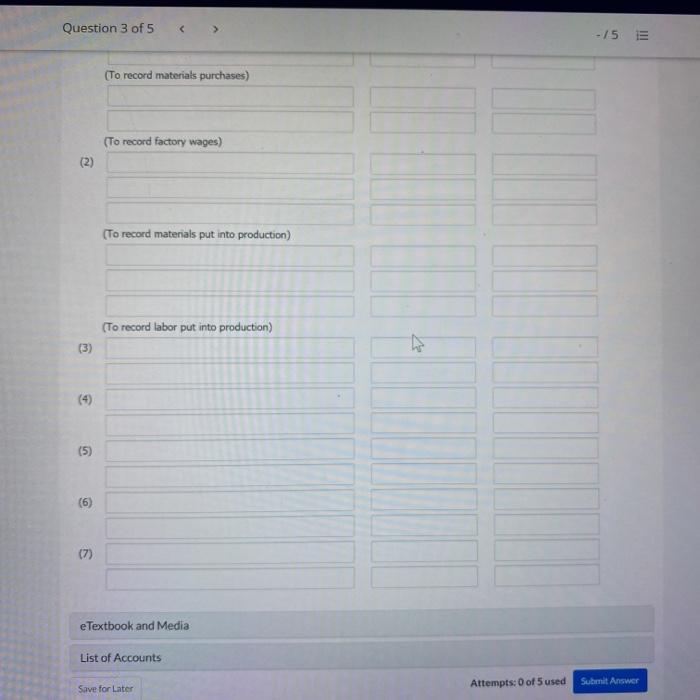

Financial Reporting

Job order cost information is used for a variety of financial reporting purposes, including:

- Income statement preparation.

- Balance sheet preparation.

- Cash flow statement preparation.

Enos Printing Corp uses job order cost information to prepare its income statement and balance sheet. The company’s income statement shows the revenue and expenses that are associated with its printing jobs. The company’s balance sheet shows the assets, liabilities, and equity that are associated with its printing jobs.

Limitations of Job Order Costing

Job order costing has a number of limitations, including:

- It can be difficult to accurately allocate overhead costs to jobs.

- It can be time-consuming and expensive to implement and maintain a job order cost system.

- It can be difficult to use job order costing to track the costs of jobs that are not easily defined.

Enos Printing Corp addresses the limitations of job order costing by using a traditional costing method to allocate overhead costs to jobs. The company also uses a variety of cost-saving measures to reduce the cost of implementing and maintaining its job order cost system.

Common Queries

What are the key advantages of using a job order cost system?

Job order cost systems offer several advantages, including accurate cost allocation to specific jobs, enhanced cost control, improved profitability analysis, and timely financial reporting.

How does Enos Printing Corp allocate overhead costs to jobs?

Enos Printing Corp utilizes a predetermined overhead rate to allocate overhead costs to jobs based on direct labor hours or machine hours worked.

What are the limitations of job order costing systems?

Job order costing systems may have limitations in industries with high-volume, repetitive production processes, as they can be time-consuming and complex to implement.